| Availability: | |

|---|---|

| Quantity: | |

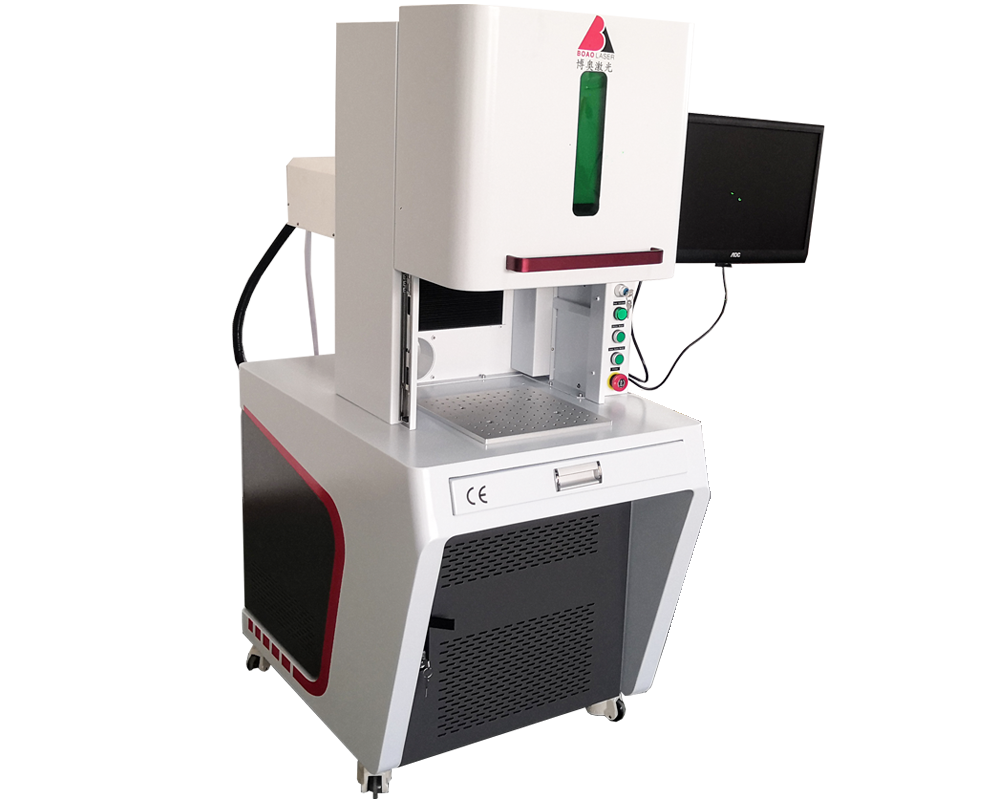

Simple Introduction

Focused UV light spot size is small , heat-affected area during processing is mimimum, so it is used in ultra-fine and special material’s marking. Since UV laser did not produce any thermal effects and burning issues, the result of the marking is precise, smooth and steep. A lot of material will absorb UV light at 355nm except copper, so UV laser are suitable for processing more types of material.

Features

1. High peak power but much less thermal effect.

2. Micro-meter or nanometer level super-fining processing.

3. Widespread applications: high absorption rate by various materials.

4. Dust-proof sealed laser cavity without condensation.

5. Much less power consumption: occupy traditional consumption of one-tenth.

6. High-speed: the speed is three to five times faster than traditonal machine.

7. Good beam Stability.

8. Long life with no maintenace.

9. Able to process multidimensional workpieces.

Advantages

Due to smallest focal spot and little affect area, UV laser could process super-precision marking and special material marking and will be the preferred product for strict requirement of the marking effect. Without heat effect, the effect of laser marking and cutting is precise, smooth and steep. Except copper, 355nm UV laser could be absorbed by many materials, so it is suitable for manufacture more material type.

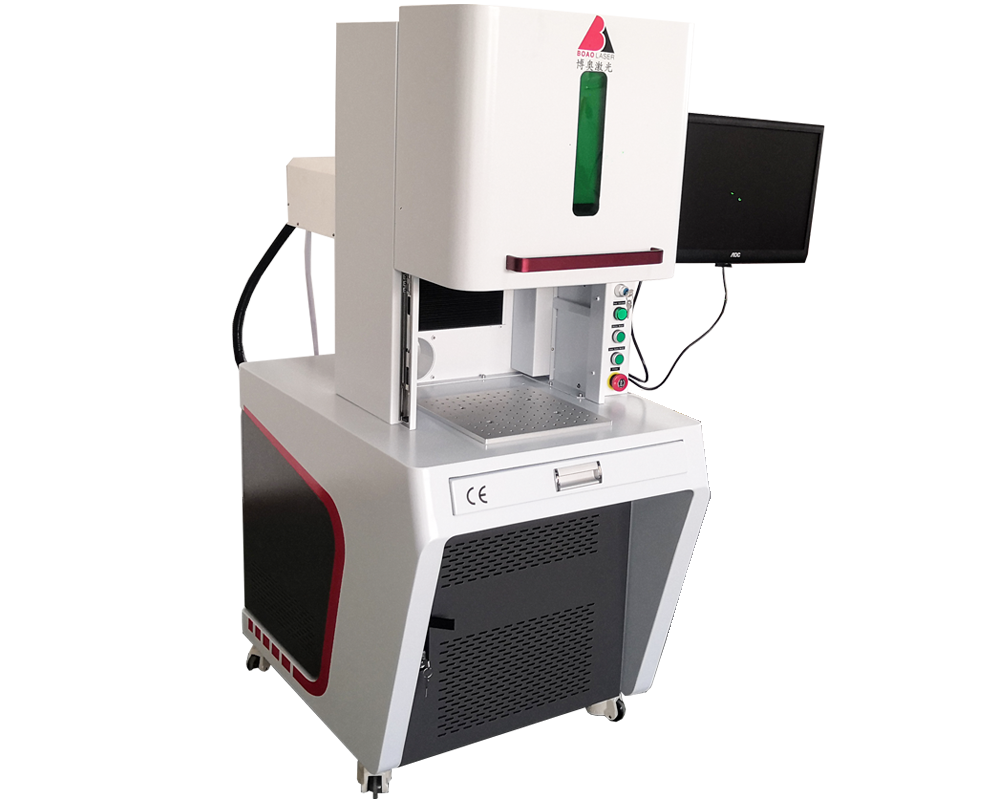

Simple Introduction

Focused UV light spot size is small , heat-affected area during processing is mimimum, so it is used in ultra-fine and special material’s marking. Since UV laser did not produce any thermal effects and burning issues, the result of the marking is precise, smooth and steep. A lot of material will absorb UV light at 355nm except copper, so UV laser are suitable for processing more types of material.

Features

1. High peak power but much less thermal effect.

2. Micro-meter or nanometer level super-fining processing.

3. Widespread applications: high absorption rate by various materials.

4. Dust-proof sealed laser cavity without condensation.

5. Much less power consumption: occupy traditional consumption of one-tenth.

6. High-speed: the speed is three to five times faster than traditonal machine.

7. Good beam Stability.

8. Long life with no maintenace.

9. Able to process multidimensional workpieces.

Advantages

Due to smallest focal spot and little affect area, UV laser could process super-precision marking and special material marking and will be the preferred product for strict requirement of the marking effect. Without heat effect, the effect of laser marking and cutting is precise, smooth and steep. Except copper, 355nm UV laser could be absorbed by many materials, so it is suitable for manufacture more material type.

Technical Parameters

Laser type | Ultraviolet laser (UV laser) |

Beam quality | ≥90% |

Laser power | 10W |

Laser wavelength | 355nm |

Working material | ND:YVO4 |

Beam mode | TEM00(≤1.2) |

Working area | 100mm×100mm |

Max marking speed | ≤12000mm/s |

Min line width | 0.01mm |

Min spot diameter | 15um |

Beam divergence | Mrad<2 |

Min character | 0.15mm |

Beam stability | Rms≤3% |

Repeat accuracy | ±0.003mm |

Pulse frequency | 20KHz-200KHz |

Electricity demand | 220v/50Hz/10A |

Cooling system | Water cooling |

Technical Parameters

Laser type | Ultraviolet laser (UV laser) |

Beam quality | ≥90% |

Laser power | 10W |

Laser wavelength | 355nm |

Working material | ND:YVO4 |

Beam mode | TEM00(≤1.2) |

Working area | 100mm×100mm |

Max marking speed | ≤12000mm/s |

Min line width | 0.01mm |

Min spot diameter | 15um |

Beam divergence | Mrad<2 |

Min character | 0.15mm |

Beam stability | Rms≤3% |

Repeat accuracy | ±0.003mm |

Pulse frequency | 20KHz-200KHz |

Electricity demand | 220v/50Hz/10A |

Cooling system | Water cooling |

Application & Materials

Main used for all kinds of glass, tft, lcd, plasma screens, textiles, thin ceramic, silicon, ic crystal, sapphire, polymers, food, drug, cosmetic, polymer materials such as wire, bottles (boxes) surface marking, and micro-holes.

Application & Materials

Main used for all kinds of glass, tft, lcd, plasma screens, textiles, thin ceramic, silicon, ic crystal, sapphire, polymers, food, drug, cosmetic, polymer materials such as wire, bottles (boxes) surface marking, and micro-holes.

content is empty!